HVAC Duct Making Machines

Mold type spiral duct machine

Product Description

Mold Type Spiral Duct Machine

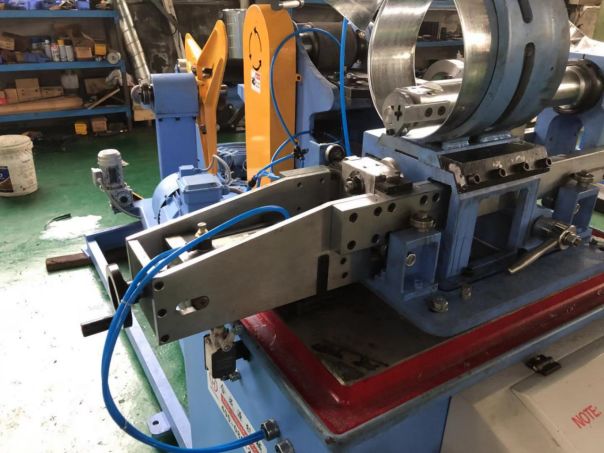

Machine pictures for reference

Mould type spiral duct machine description:

This mould type tubeformer is designed to automatically form spiral duct for HVAC round duct progress!

It is an advanced spiral duct forming line with more reliable performance due to its fixed mould design!

Each mould will form spiral tube of one fixed diameter.

Features:

1.The equipment bite method is hydraulic drive, which is different from the motor drive used in the previous simple fixed mold models. The hydraulic drive has more power and good bite effect;

2.The material carrier of this model is different from the simple solid mold model. This model uses a split tray, which is a separate part, and the production is more stable. The brake method is used to make the production and feeding process more stable.

3.The equipment provides an adjustable processing speed function to provide customers with stable and efficient production requirements, and the equipment provides fixed-length cutting

4. Provide double cutting methods for customers to choose

a, Hob cutting-no sparks, no burrs, no noise

b, Plasma cutting-no burr, economical, best choice for large pipe diameter, best choice for plate thickness

5. Adopt PLC control system, touch screen operation, PLC adopts Taiwan Delta, most of the electrical is Schneider/Chint (if you need to customize, you need to inform in advance), the operating system includes equipment operation and cutting data, such as equipment bottom wheel lifting , Cutting mode selection, data setting, production quantity, etc.

The equipment system is self-developed by our engineers to ensure the long-term use of customers and provide timely and stable technical support

The equipment contains two production modes:

Semi-automatic mode-After starting the equipment, click on the screen to cut to cut. This mode is suitable for the continuous switching of round tubes of various sizes and small quantities;

Fully automatic mode-start the equipment, enable the automatic mode, set the cutting quantity, automatically produce automatic cutting, and automatically stop working when the set quantity is reached;

6. The molding part of the equipment is made of CR13 and CR12 materials, which are completed through processing and quenching processes to ensure the stability of equipment use

The main board and gearbox of the equipment are made of cast iron, which has higher load bearing pressure, more durability, better wear resistance, and better shock absorption than steel plates

7.The equipment adopts the frequency conversion reducer of the listed company Guomao Group, which has stable quality and stable transmission. It adopts 11KW power and large driving force.

8.The equipment has an automatic turning function, which improves production efficiency and reduces labor

9. As a professional manufacturer, equipment procurement from raw materials-equipment parts processing-assembly are all completed by our company, eliminating the mode of processing that only assembly but not production

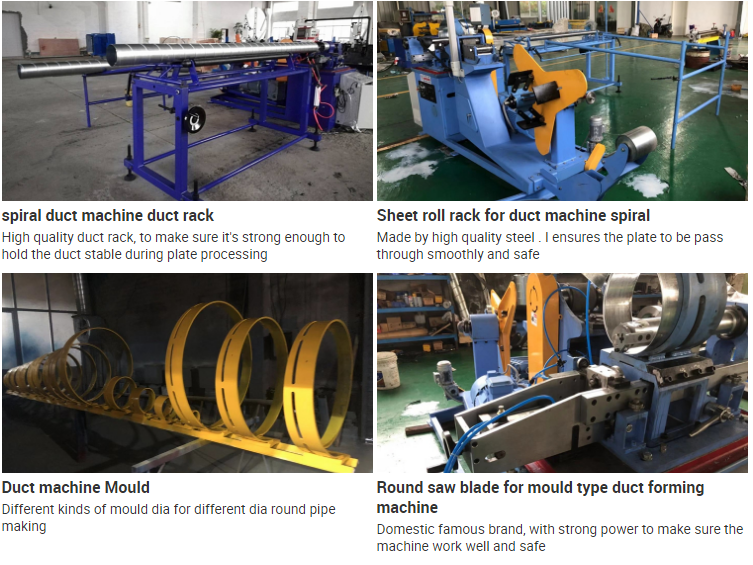

Components

Main components:

France Schneider Electric

Taiwan Facon system

Main motor:Chinese famous brand Zhejiang fangli

Machine frame: Q235A hard steel

Technical Parameters

Main technical parameters

Type | Diameter (mm) | Process plate thickness (mm) | Processing speed (m/min) | Main power (kw) | Weight (kg) | Dimension (mm) |

SBJX-1600 | Φ100-1600mm | 0.4-1.2mm | 0-50 | 11 | 1800 | 4000*3300*1900mm |

Online Inquiry

E-mail:rbzg@rbqlty.com

Address: Bowang Industrial Park, Bowang District, Ma'anshan, Anhui

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.