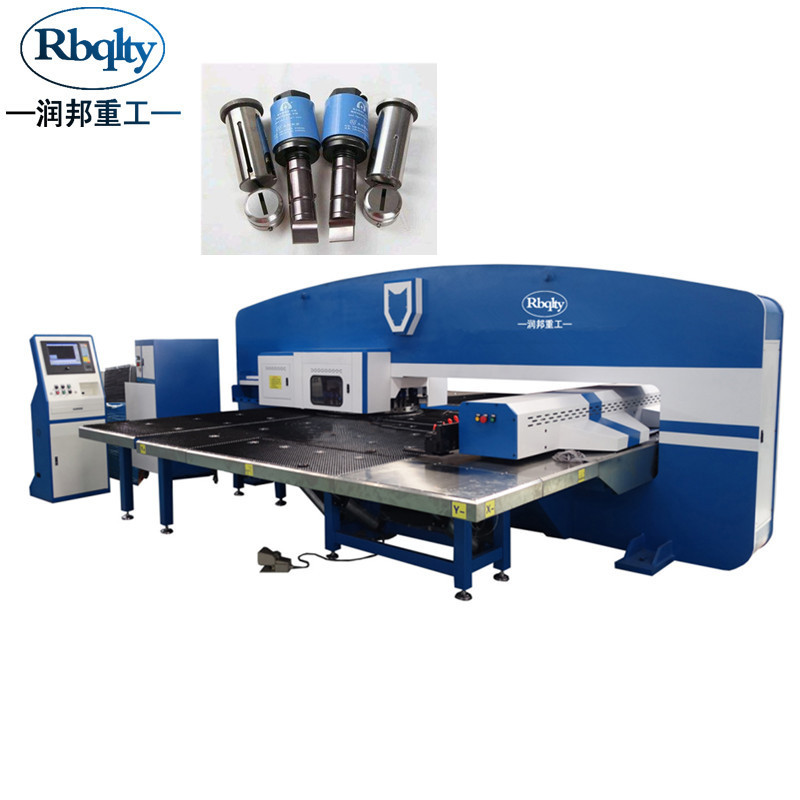

Punching Press Machine

RB3024-24 station 30T Hydraulic Turret punching machine

Product Description

RB3024-24 station 30T Hydraulic Turret punching machine

Machine pictures for reference

- Main Specification And Characters

(1)wheel disc:

1.The turret wheel disc is made of 45 # carbon steel and is processed by drawing temper;It dopts special clamps for the pair processing,so the coaxial degree of upper and lower die is guaranteed, and the positioning accuracy of die is greatly extended. Adopting the thin turret mosaic wheel disc structure, while reducing the gravity of the die of wheel disc, it still keeps the long guide structure, ensuring the mould's guiding stability.

2.The company is equipped with the large imported three coordinate measuring instrument (Sweden hxcon), and the wheel disc is installed after being tested qualified. (other measurement tools cannot detect the the division value of wheel disc.)

(2)、Rotating position (rotating position) : adopt the turbine worm drive method, the transmission precision is high.

(3)、The international matching pneumatic components guarantee the reliability of the machine performance.

(4)、Adopt imported large lead ball screw, linear guide.

(5)、It adopts universal ball, brush plate hybrid worktable, reducing the noise and vibration when the machine works, and played a very good protection on the surface of the board being processed, which can effectively prevent plate surface scratches;Worktable periphery and part of worktable adopts stainless steel protection,making it beautiful and generous, firm and durable. The drag chain of data line protection is moved from the traditional way to the side of the machine, reducing the workbench blade, preventing scraps to plate, the collision to plate. The assembly of linear guide and screw rod is calibrated with laser collimator to ensure the straightness and the degree of parallelism of each linear guide and screw.

(6)、It adopts the "O" type (closed) steel plate welded machine body, with high temperature tempering treatment to eliminate the internal stress and avoid the fuselage distortion. It adopts one clamping processing technology on feeding bracket, avoid the repositioning of second installation of clamping so that the parallel degree and degree of tolerance is too large to make the feeding speed instability, damage guide rail sliding block and screw nut ball; It is equipped with adjusting bolt on the outside of feeding bracket, so that the feeding plate has the fine adjustment function, which solves the disadvantages of natural deformation which cannot be adjusted due to the long service life.

(7)、The welding parts and casting parts are treated with tempering and the internal stress is eliminated.

(8)、It adopts floating pneumatic clamp, the holding force is large and the feeding is stable. The whole body type is swallow-tail type drag plate, the rigidity is good, the clamping clamp moves convenient, the beam adopts the double guide rail design, the feed material is stable, the positioning is accurate.

(9)、The system has automatic clamp protection function, which can not be stamped in the protected area, and only displacement movement is used to ensure the continuity of the operation of the program.

(10)、It adopts Nanjing famous brand hydraulic station. Equipped with servo proportional valve, the world's top brand - Germany Rexroth), controller, full closed-loop control of displacement sensor, constantly monitor the punch position;It is of high control accuracy and can meet the requirements of any stamping process.

(11)、Automatic selection process: the system can automatically select the most suitable mold to process. The display simulation of machining trajectory and path can be carried out. If multiple parts are laid out on the big board, the material can be saved to the maximum extent and the utilization rate of materials can be improved.

(12)、Display of wheel disc rotary mould, display of stamping time, display of processing quantity, mold life (stamping times) display.

(13)、The side of machine stores mold tools, avoid the mold damage because of the Irregular placement of mold, effectively protect the mold, to ensure the mold stamping effect, extend the service life of the mold.

Quality control measures

(1)、Passes ISO9001 quality certification,strictly follows this execution in product design, manufacturing, sales, service process.

(2)、The computer network center is equipped with CAD design and CAP assisted technology, with strong product development and design, manufacturing and modification ability.

(3)、The welding parts of machine body, sliding block and worktable are used for annealing after welding, so as to eliminate welding stress and ensure its high strength and high stability.

(4)、Complete large, fine, exiguity equipment and advanced processing technology to ensure the machining accuracy of machine parts.

(5)、Perfect test method (national level 1 measurement unit), high quality inspection personnel, guarantees the overall quality of machine parts and external purchase

(6)、Main measuring instrument

1) | 2671 type pressure tester |

2) | YBDL-1 type protection ground circuit continuity tester |

3) | ND6 type impulse precision sound level meter |

4) | YD-15 dynamic resistance strain instrument |

5) | QCJ type paint film impact test device |

6) | QFZ-2 type coating adhesion test instrument |

7) | QBY Varnished coating hardness tester |

8) | Hydraulic components test bed |

9) | HV-4B type Microcomputer high speed determination of carbon sulfur meter |

10) | WF-30 type universal material testing machine |

11) | XJL-02 type upright metallurgical microscope |

12) | HLN-11A Digital hardness tester |

13) | HRC-150 Rockwell apparatus |

14) | Magnetic defect detector |

15) | ND6 precision sound level meter |

16) | XZR-B type Oil pollution contrast microscope |

17) | XZR-J type Oil contamination detection microscope |

18) | JX-11 type Digital universal tool microscope |

19) | JD18 type universal projection length measuring instrument |

Components

List of main components of the equipment

Item | Model-Part Number | Manufacturer | |

CNC System | 808D | SIEMENS | |

Servo Motor |

| SIEMENS | |

Breaker |

| Schneider | |

Contactor |

| Schneider | |

Relay |

| OMRON | |

Proximity Switch |

| OMRON | |

Programming Software | CNCKAD | As gift | |

Transmission Parts | |||

Linear slider |

| HIWIN | |

Ballscrew |

| TBI | |

Ballscrew Support Bearing |

| NSK | |

Supporting Bearing for Turret |

| NSK | |

Wheel Bearing |

| NSK | |

Main Transmission Bearing |

| NSK | |

Pneumatic Parts | |||

Three joints | BFL3000 | AIRTAC/SMC | |

Electromagnetic Valve |

| AIRTAC/SMC | |

Magnetic Switch |

| AIRTAC/SMC | |

Coupling |

| NSK | |

Tools | |||

24 standard tools (12A/8B/2C/2D) | Standard | China | |

Welded O type press | Siemens 808D CNC system |

|  |

Hydraulic station | Siemens Servo motor |

|  |

TBI ballscrew | HIWIN linear slider |

|  |

Pneumatic floating clamp | Standard AMADA thick turret |

|

|

Description of device content

(1) Control system:Germany Siemens 808D advanced CNC system, closed loop control,Cooperate with a complete set of Germany's Siemens servo module can realize 4 axis drive at the same time;When equipped with USB, internet access, R232 communication interface,it can realize the foreground and background programming.It adopts CNCKAD programming software, brings their own mold database management system, setting-up its automated cutter, automaticly optimizes processing path, realize automatic conversion process of AutoCad graphics.The function of plate automatic relocation helps to realize the no-dead zone processing.The operation is simple and can achieve one-click operation;

- Stamping machine body: closed type of machine, overall tempering treatment, rigid and undistorted, running smoothly;

- Turret mechanism: It adopts the high strength wear resistant ductile iron HT600 thick-turret with thickness of 80 mm, the internal stress is removed by heat treatment to ensure its good rigidity, high stability, strong shock resistance, high orientation precision, and the partial load resistance is strong, greatly improving the service life of the mold;

(4) Mold: adopting international standard thick turret mould for easy maintenance and purchase;

(5) Motor/drive: Siemens servo motor, stable and reliable, higher precision;

(6) Drive screw: adopting the Taiwan ball screw,with accurate precision.

(7) Linear guide: Taiwan linear guide, applying a wider flange type sliding block;

(8)Positioning cylinder: famous-brand cylinder, precise locking and positioning

(9)Speed reducer motor: precise turbo-worm reducer motor, with its own brake function, reduce the impact on the servo motor after the high-speed operation of the mold disc, and guarantee the accuracy of the rotation of the turret at high speed;

(10) Clamping forceps: floating pneumatic clamps can be used to float with the plate to avoid distortion of plate.

- Workbench: The workbench is made of 5300 mm wide high quality brush mixed with steel ball, to ensure that the entire sheet on the workbench during the stamping process, avoiding that the plate go beyond the workbench to hurt the workers, the workbench made of brush mixes with universal ball countertops greatly reduces the friction of plate movement,effectively protects plate surface;

(12) Lubrication system: The oil supply station with the control system is adopted, and the main transmission mechanism, such as guide rail and screw, can be automatically lubricated in accordance with the preset time.

(13) Main electrical components: relay, photoelectric sensor, contactor and so on all adopts omron, schneider and other famous brand electronic components, which guarantees long-term equipment safety and stability.

Mould parts

(1) Mold distribution: 12A/8B/2C/2D

(2) Size range of each station:

A Size range of station:Ø1.6-12.7mm

B Size range of station:Ø12.8-31.7mm

C Size range of station:Ø31.8-50.7mm

D Size range of station:Ø50.8-88.9mm

Fittings

No. | Description | Type specification | Manufacturer | Qty |

1 | Anchor bolt | M12 | | 1 set |

2 | Waste dolly | Emblem mark | | 1 set |

3 | Software, circuit diagrams | Electronic version | | 1 set |

4 | Certificate of quality | Articles-Whitepapers、Electronic version | | 1 set |

5 | Operating manual | Articles-Whitepapers、Electronic version | | 1 set |

6 | Internal hexagonal wrench | Emblem mark | | 1set |

Technical Parameters

Main technical datas of equipment

- Stamping force:300KN;

- Number of stations: 24 stations;

- Positioning effective stroke:1250 *2500(Re-position to 1250*5000mm)

- Secondary re locations: standard equipped;

- Working accuracy:±0.1mm;

- Thickness of the largest processed plate:carbon steel t≤4mm;

- Control axis number: 4 axis(X、Y、T、C);

- Rated power:18.2KW;

- Plant internal environment:Temperature: 5℃~40℃, humidity: 40% ~ 90%, no harmful and corrosive gas and dust in the environment.

- Compressed Air Pressure:≥0.8Mpa

- Dynamic voltage: three phase four lines 380V±10%, frequency:50Hz±1Hz

Online Inquiry