Ironworker machine

E21 Q35Y Hydraulic Ironworker Machine

Product Description

Hydraulic punching and shearing ironworker machine

Applications:

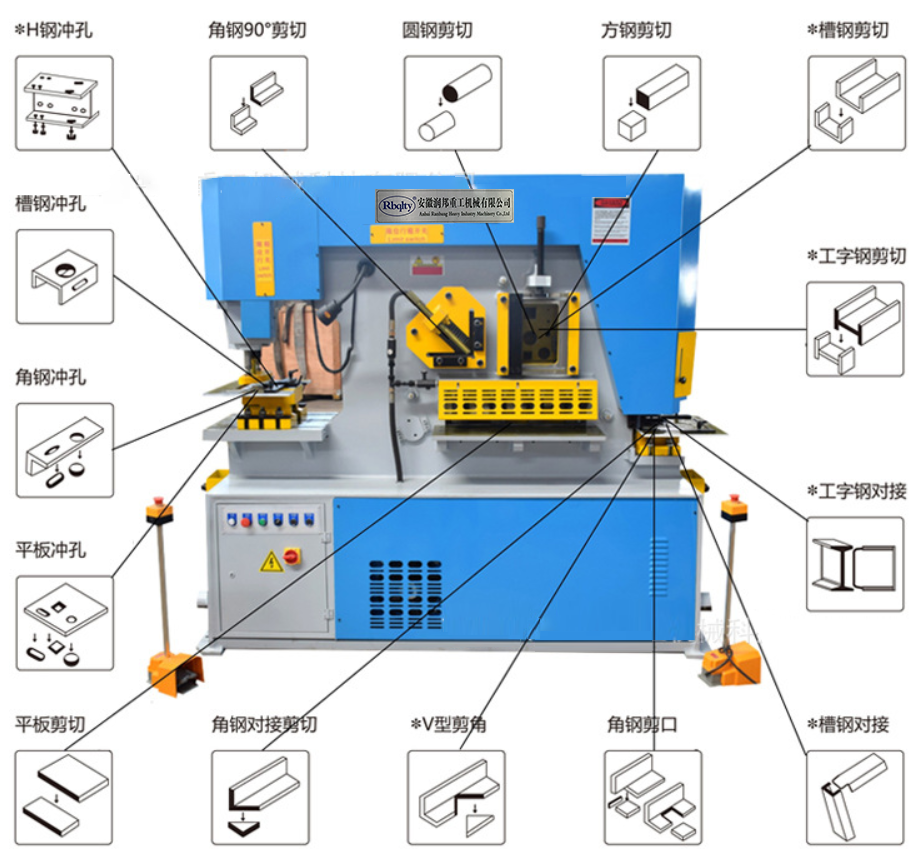

While not meant for accuracy or high production needs, an Ironworker can make quick work of many different types of materials and perform many different processes necessary in a Fab Shop. Materials like: Plate, Tube, Angle and Rod stock can all be processed on an Ironworker. Capable of Punching, Shearing, Bending, Notching and Coping (a type of shearing) an Ironworker is an extremely flexible, versatile and necessary machine in any Fabrication or Weld Shop.

Standard function

1. Robust and accurate steel frame

2. Large punch table with scales

3. Removable bolster for punching flanges and channel and beam

4. 2 independent hydraulic cylinders

5. 2 shielded foot controls

6. 2 Separate Die Openings for over sized punching

7. 5 working stations for wide applications

8. power inching on all 5 work stations

9. plate shear support table and notching table

10. adjustable stroke controls with indicators on both cylinders

11. punching machine: Movable work light

Optional function

1. optional overload protection on hydraulic system

2. optional electric back gauge

3. optional bending attachment

4. optional two cylinder works simultaneously

Components

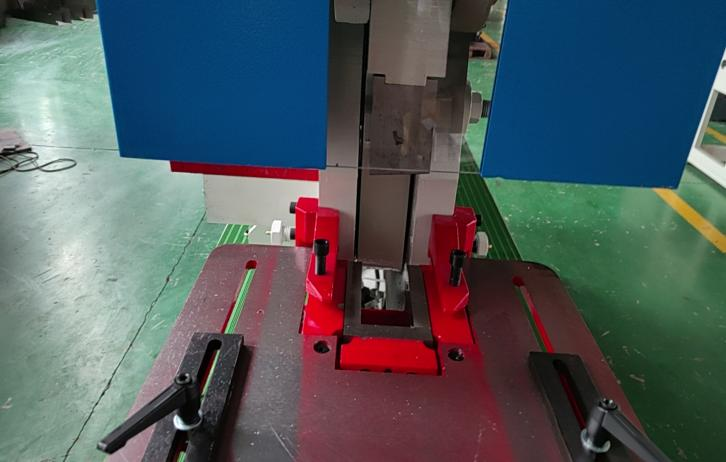

Angle Steel Cutting cutting part-For angle steel 90 and 45 degree cutting Angle Steel Cutting cutting part-For angle steel 90 and 45 degree cutting |  Profile cutting part: round&square bar/C channel/I beam/U steel Profile cutting part: round&square bar/C channel/I beam/U steel |

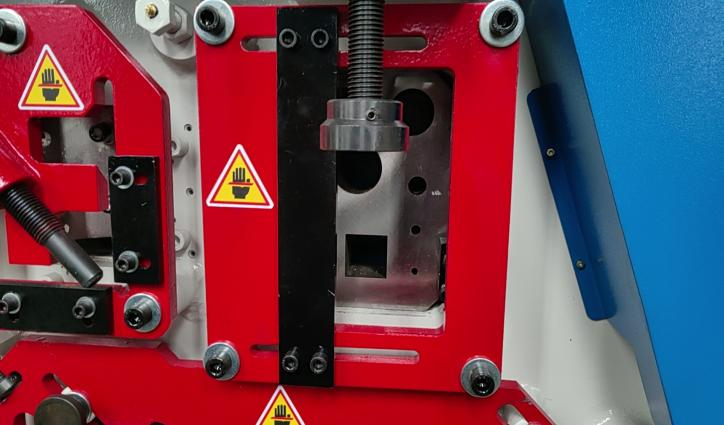

Hole punching part, can update to do bending with bending tooling |  Notching part |

Steel plate cutting part |  Main motor and pump |

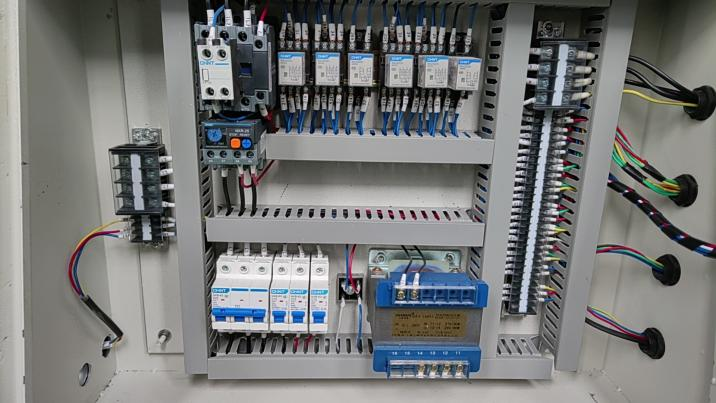

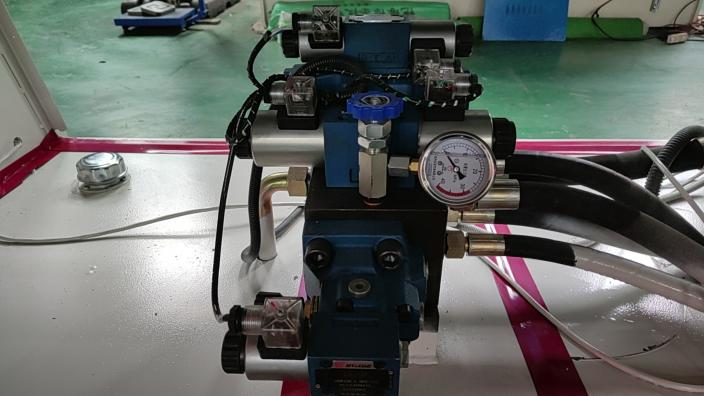

Electric part |  Hydraulic system-hydraulic valve |

Differeent kinds of tooling available |  plate holder-for optional |

Machine components

Grease seal: Japan NOK

Oil cylinder: Anhui Wuyang

Hydraulic: German BOSCH

Gear Pump--Shanghai HANGFA

Motor: German Siemens

Electric system: France Schneider;

List of the standard tooling

1. 1 set of punching tooling (single hole punching)

2. 1 set of round bar square bar

3. 1 set of plate cutting

4. 1 set of angle steel cutting

5. 1 set of notching, corner cutting

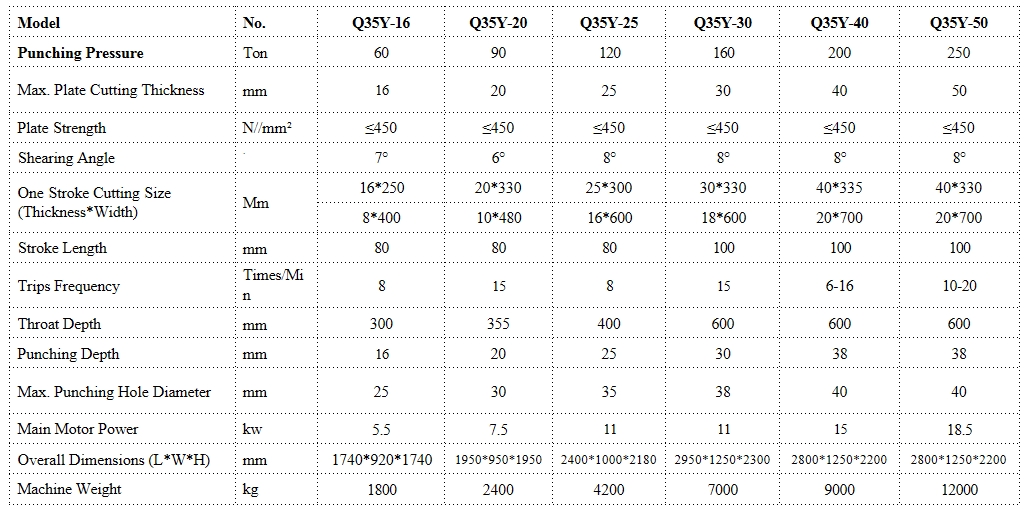

Technical Parameters

SPEC

Capacity

Online Inquiry

E-mail:rbzg@rbqlty.com

Address: Bowang Industrial Park, Bowang District, Ma'anshan, Anhui

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.