Punching Press Machine

Mechanical Press Machine

Product Description

J23 series Open back inclining mechanical press for punching

Mechanical punch presses generate power mechanically, using a motor that is connected to a crankshaft, which cycles the ram for each operation using flywheels and belts. The flywheel builds up pressure and then releases, transferring energy to the primary side in the process. The strokes of a mechanical press are called single-, double- or triple-action, based on the number of ram or slides it has. It can be adjusted within limitations.

JB23 series Open Eccentric Presses is a general-purpose presses, suitable for forming, blanking, punching, bending and other cold stamping process.

C-frame Casting fuselage,maximum rigidity and minimum deflection for accurate parts and long tool life. body can be tilted, , high rigidity and less deformation Compact. Thick plates and large columns provide you with the stable platform you need for your demanding application.

The Machine use Rigid rotated bond clutch rigid and well supported. The clutch gives continuous strokes for mass production.

Crank shaft is made of special alloy steel machined to close accuracy and fitted in bronze bushes for smooth working, longer life & accuracy.

Properly sized flywheel, is made of high grade cast iron, for storing and releasing adequate energy for the pressing operations, and properly balanced for smooth running.

Gear are of steel cast or fabricated. Gear teeth are generated by precision hobbing machine.

Machine is with both hands button and foot switch control: anti-tie down, non-repeat controls with ring guards; conforms to OSHA.

8.Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate.

Machine pictures for reference

Advantages:

1. Economical and low price

2. Easy to operate, basically no technical requirements, and can be operated by ordinary workers

3. Heavy body, after VSR elimination, ensures the durability of the body

4. Low maintenance cost in the later stage, few wearing parts

Components

Machine Detail images

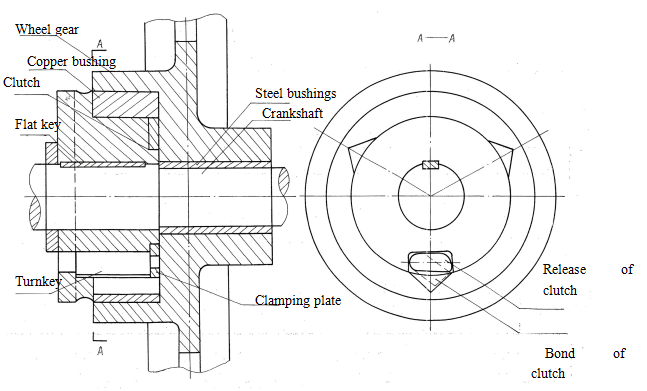

Assembly drawing of clutch

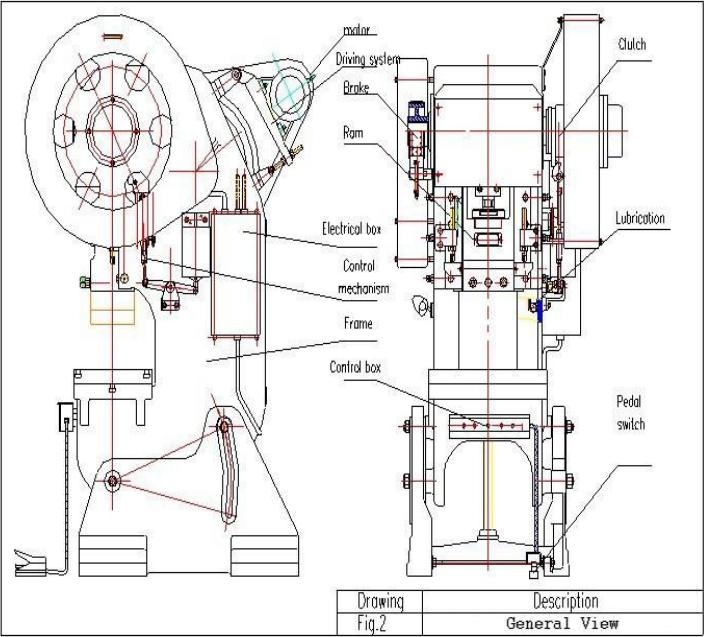

General view of machine

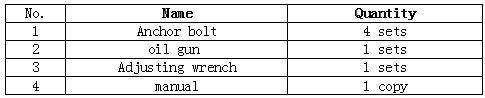

Punch accessories list

Technical Parameters

Technical Parameters

Nu | Name | Unit | 10T | 16T | 25T | 40T | 63T | 80T | 100T | |

1 | Nominal Pressure | Kn | 100 | 160 | 250 | 400 | 630 | 800 | 1000 | |

2 | Slider stroke | mm | 50 | 60 | 70 | 100 | 100 | 115 | 130 | |

3 | Nominal Pressure itinerary | mm | 1 | 1.5 | 2 | 8 | 6 | 7 | 9 | |

4 | Number of strokes | min/times | 140 | 120 | 60 | 50 | 50 | 45 | 40 | |

5 | Max mold height | mm | 160 | 150 | 220 | 220 | 260 | 265 | 260 | |

6 | Slider adjustment | mm | 40 | 40 | 50 | 60 | 60 | 60 | 60 | |

7 | Worktable size(FB*LR) | mm | 210*350 | 450x290 | 320x530 | 420x640 | 450x700 | 480*745 | 600*900 | |

8 | Table blanking hole diameter | mm | 95 | 120 | 125 | 160 | 170 | 170 | ||

9 | Size of die shank hole (DIA*Depth) | mm | 30*50 | 35x50 | 40x50 | ∮50*70 | 50x70 | ∮60*80 | 60x70 | |

10 | Slider center to fuselage distance | mm | 130 | 180 | 235 | 255 | 255 | 330 | ||

11 | Distance between two columns of fuselage | mm | 180 | 200 | 240 | 300 | 320 | 300 | 380 | |

12 | Plate thickness | mm | 35 | 35 | 80 | 80 | 85 | 100 | ||

13 | Main motor power | Kw | 1.1 | 1.5 | 2.2 | 4.0 | 5.5 | 7.5 | 7.5 | |

14 | Size | L | mm | 900 | 1100 | 1100 | 1500 | 1710 | 1790 | 1920 |

|

| W | mm | 550 | 750 | 850 | 1100 | 1250 | 1350 | 1370 |

|

| H | mm | 1550 | 1800 | 1980 | 2450 | 2500 | 2650 | 2770 |

15 | Main motor Rotating speed | R/min | 1400 | 1400 | 1400 | 1440 | 1440 |

| 1440 | |

16 | Main motor model |

| YE2---100L---4 | YE2---100L---4 | YE2---100L---4 | Y132M-4 | Y112M-4 | Y132M-4 | Y160M-4 | |

17 | Size of the bottom surface of the slider(FB*LR) | mm | 100*140 | 120*170 | 220*260 | 255*310 | 250*320 | |||

18 | Machine weight approx | kg | 300 | 1400 | ||||||

19 | Body can be tilted | degree | 30 | |||||||

Online Inquiry

E-mail:rbzg@rbqlty.com

Address: Bowang Industrial Park, Bowang District, Ma'anshan, Anhui

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.