HVAC Duct Making Machines

HVAC Auto duct line II

Product Description

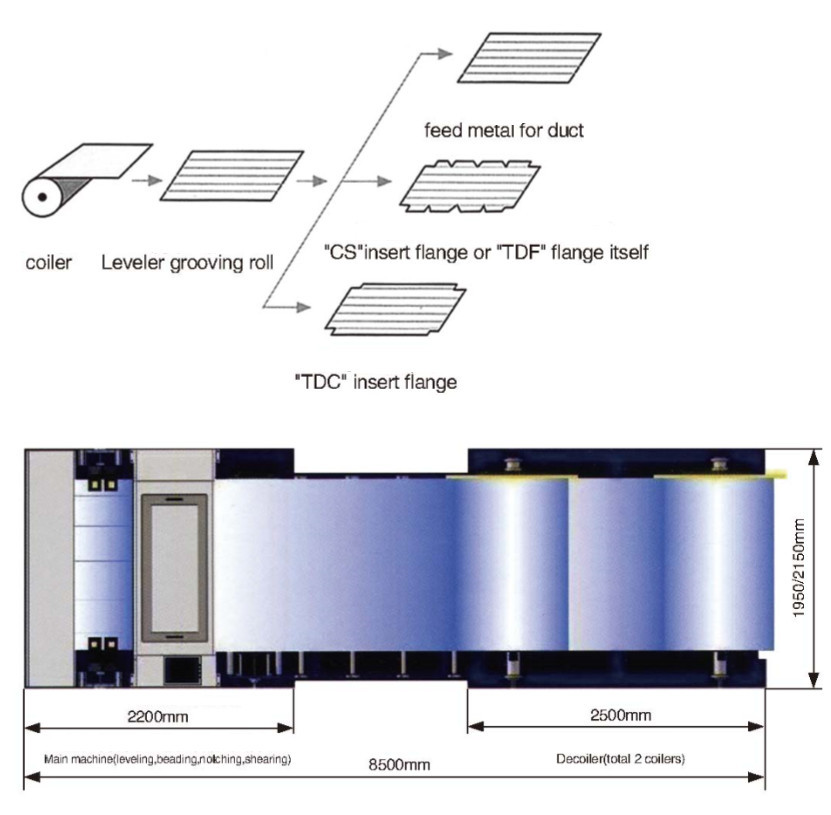

Auto duct line II

Machine pictures for reference

FUNCTION

Duct production line 2 can drive blanking for duct and TDF flange forming machine at the same time. Combined with TDF flange forming machine, rolling reel machine, crimping machine and relevant corner code, duct production line 2 can produce high-quality proeducts.

PERFORMANCE FEATURES

1. Alumimium alloy suspension arm makes the machine easy to operate;

2. The build-in control cabinet reduces wiring as a whole structure and makes it easy to move;

3. The imported configuaration is vert stable and comfortable to use.

Working processing:

Basic equipment:

1.Electric feeding rack 1 set

2.Leveling ,beading equipment one group

3.Hydraulic angle shearing machine 4 sets including die

4.Hydraulic plate shearing device, hydraulic bending device

5.Mitsubishi CNC control, software(in English)

Components

Main components:

1.France Schneider Electric

2.OMRON encoder

3.Control system: Mitsubishi

4.Main motor:Siemens or Chinese famous brand

Technical Parameters

Main technical parameters

Model | Plate thickness range(mm) | Plate width(mm) | Max working speed (m/min) | Max coiler weight (Kg) | Weight (Kg) | Dimensions(mm) |

HD-1250 | 0.3-1.2 | 1250 | 16 | 6000*2 | 3500 | 5000*2160*1450 |

Online Inquiry

E-mail:rbzg@rbqlty.com

Address: Bowang Industrial Park, Bowang District, Ma'anshan, Anhui

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.