HVAC Duct Making Machines

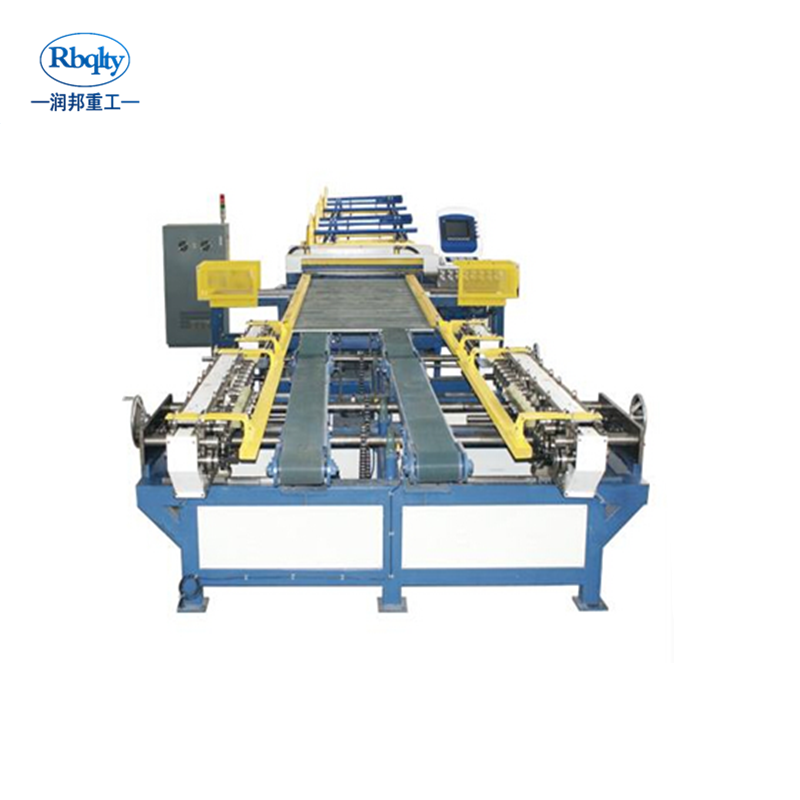

Ventilation Duct Manufacturing Machine Auto duct line IV

Name: Auto Line 4 Ventilation Duct Manufacturing Machine Brand :Rbqlty Category :HVAC DUCT MACHINE Model Type :SDL-IV Price: CONSULT

Product Description

Auto duct line IV

Machine pictures for reference

Auto duct line IV description

The max feeding speed of this line is 15m/min. The length tolerance is ±0.5mm and diagonal tolerance is ±0.8mm.

This line can simultaneously cut metals for ducts of different sizes.

Function:

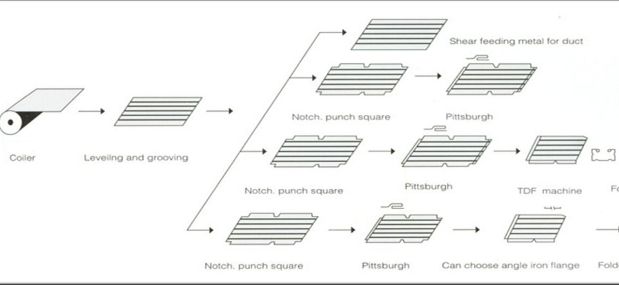

It is mainly for uncoiling,leveling,beading,punching,locking ,bilaterally angle steel or

TDF flange forming.Because of its small space requirement and easy to install and operate ,people also call call it "small line 5".

Performance Features:

1.All the rolling reel and made of bearing steel so that the lifetime prolongs by more than 5 times

2.Under the material saving mode of CNC system, machine can withdraw material automatically after finishing tasks

3. With production memory functions, the production order can be tracked and checked.

Components

Basic equipment:

1.Electric feeding rack 1 set

2.Leveling ,beading equipment one group

3.Hydraulic angle shearing machine 4 sets including die

4.Hydraulic plate shearing device, hydraulic bending device

5.Mitsubishi CNC control, software(in English)

Main components:

1.France Schneider Electric

2.OMRON encoder

3.Control system: 台湾Mitsubishi (三菱)

4.Main motor:Siemens or Chinese famous brand

Working processing:

Technical Parameters

Main technical parameters

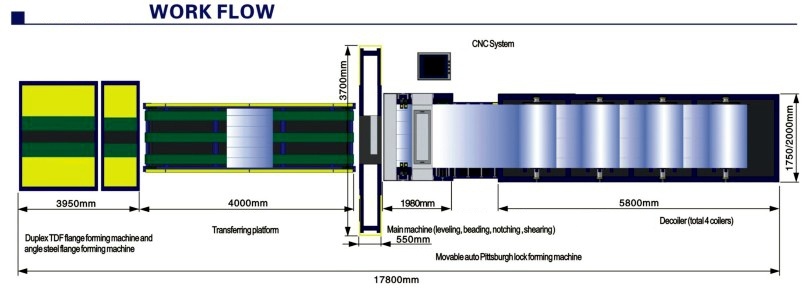

| Model | SDL-IV | 1. Electric feeding racks 2 sets 4 coil cradles 2. Leveling ,beading,notching, cutting equipment 1 set 3. High speed lock former device 4. Transferring platform 5. A duplex TDF flange forming machine (Optional a duplex angle steel flange forming machine) 6. A CNC controller, software | |

| Plate Thickness Range (mm) | 0.5-1.2 | ||

| Max-width(standard) (mm) | 1250 | 1500 | |

| Max-working Speed (m/min) | 15 | ||

| Coiler Max-weight (kg) | 7000 | ||

| Dimension | 18800 | 18800 | |

| 3500 | 4000 | ||

| 1500 | 1500 | ||

| Main Power (kw) | 26 | ||

| Weight (kg) | 9000 | 10000 | |

Online Inquiry

E-mail:rbzg@rbqlty.com

Address: Bowang Industrial Park, Bowang District, Ma'anshan, Anhui

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.