Other Products Machine

Rbqlty Industrial Welding Robot

Name :Automatic Multi-joint industrial Welding Robot Brand :Rbqlty Category :Other Products Machine Model Type :RB10-1440 Price: CONSULT

Product Description

Welding Robot

Components Introduction

Welding robots are industrial robots engaged in welding (including cutting and spraying). According to the definition of the International Organization for Standardization (ISO) industrial robot is a standard welding robot, an industrial robot is a multi-purpose, reprogrammable automatic control manipulator (Manipulator), with three or more programmable axes for field of industrial automation. In order to adapt to different purposes, the mechanical interface of the last axis of the robot is usually a connecting flange, which can be connected to different tools or end effectors. The welding robot is equipped with welding tongs or welding (cutting) guns on the flange of the final axis of the industrial robot, so that it can perform welding, cutting or thermal spraying.

With the development of electronic technology, computer technology, numerical control and robot technology, automatic welding robot has been used in production since the 1960s, and its technology has become increasingly mature. Therefore, it has been widely used in various industries.

Ⅰ.Machine pictures for reference

Components

Machine Configuration

1 | Robot configuration | robot | MR10W-1440 MR12-2010 | 1 | Working radius 1440mm

Working radius 2010mm |

2 |

| Control cabinet |

| 1 | The 6-axis drive control integrated machine covers most of the external interfaces required by users: 16 input and output interfaces, 1 Ethernet, 2 IN/OUT analog signal interfaces, and retains two customizable function expansion interfaces, which can be used as CAN&485 and encoder signal interfaces. |

3 |

| Teaching pendant | T30 | 1 | TFT large touch screen version LINUX system |

4 | Welder | Welding power supply | Ota | 1 | Contains Aotai IIAG-500RP, anti-collision welding gun, wire feeder, wire reel, wire feeding hose, high-flexible cable, and two-station reservation box. |

WELDING MACHINE SPECIFICATION

1.MAG-350RL

Rated input voltage/frequency (V/HZ) | Three-phase 380±10% /50 |

Rated input capacity (KVA) | 14 |

Rated input current (A) | 21 |

Rated output voltage (V) | 31.5 |

Rated duty cycle (%) | 60 |

Output no-load voltage (V) | 96 |

Output current/voltage range (A/V) | 60/17-350/31.5 |

Wire diameter (MM) | 0.8, 1.0, 1.2 |

Gas flow (L/MIN) | 15-20 |

Gun cooling method | Air cooling |

Enclosure protection grade | IP23 |

Insulation grade | H |

Dimensions LXWXH (CM) | 66x32x56 |

Weight (KG) | 55 |

2.Pulse MLG-500RP Super Plus

Rated input voltage/frequency (V/HZ) | Three-phase 380±15% 50/60 |

Rated input capacity (KVA) | 24 |

Rated input current (A) | 38 |

Rated output voltage (V) | 39 |

Rated duty cycle (%) | 100 |

Output no-load voltage (V) | 76 |

Output current/voltage range (A/V) | 30/15.5-500/39 |

Wire diameter (MM) | 0.8, 1.0, 1.2, 1.4, 1.6 |

Gas flow (L/MIN) | 15-20 |

Gun cooling method | Air cooling |

Enclosure protection grade | IP23 |

Insulation grade | H |

Dimensions LXWXH (CM) | 66x32x56 |

Weight (KG) | 55 |

3.NBC 500RP Plus

Rated input voltage/frequency (V/HZ) | Three-phase 380±15% 50/60 |

Rated input capacity (KVA) | 24 |

Rated input current (A) | 38 |

Rated output voltage (V) | 39 |

Rated duty cycle (%) | 100 |

Output no-load voltage (V) | 76 |

Output current/voltage range (A/V) | 30/15.5-500/39 |

Wire diameter (MM) | 0.8, 1.0, 1.2, 1.4, 1.6 |

Gas flow (L/MIN) | 15-20 |

Gun cooling method | Air cooling |

Enclosure protection grade | IP23 |

Insulation grade | H |

Dimensions LXWXH (CM) | 66x32x56 |

Weight (KG) | 55 |

Technical Parameters

1.MR10W-1400-D

Robot Technical parameter

Model | MR10W-1400-D | ||

Axis | 6 | ||

Motion radius | 1440mm | ||

Power capacity | 4.5KVA | ||

Payload | 10KG | ||

Repeatability | ±0.05mm | ||

Robot mass | 210KG | ||

Power capacity | Ф10 | ||

Protection class | IP56/IP67 | ||

Signals | Standard 16 in/16 out 24VDC | ||

Install | Floor-standing/bracket-type/inverted-hanging | ||

Moving range&speed | |||

Axis 1 S | Moving speed 285°/s | Moving range ±167° | |

Axis 2 L | Moving speed 247°/s | Moving range from +80°to -145° | |

Axis 3 U | Moving speed 285°/s | Moving range from +145°to -75° | |

Axis 4 R | Moving speed 392°/s | Moving range ±190° | |

Axis 5 B | Moving speed 272°/s | Moving range from +50°to -210° | |

Axis 6 T | Moving speed 1353°/s | Moving range ±220° | |

Axis 4 R(N.m) | 103.5 | ||

Axis 5 B (N.m) | 51.84 | ||

Axis 6 T (N.m) | 32.64 | ||

Control cabinet parameters

Overall dimension | 700(width)*530(depth)*740(height)mm(including protrusions) |

Rough quality | 60KG |

Cooling method | Direct cooling |

Power specifications | AC220V 50/60HZ |

Grounding | Industrial grounding (special grounding with grounding resistance below 1000) |

Input/0utput signal | General signal: input 16, output 16 (16 in 16 out) |

Position control method | Serial communication method EtherCAT.TCP/IP |

Memory capacity | JOB: 200,000 steps, 10,000 robot commands (200M in total) |

LAN(Host link) | Ethercat (1) TCP/IP (1) |

Control mode | Software servo <position control> |

Ambient temperature | When powered on: 0~+45℃, when stored: -20~+60℃ |

Driver unit | Servo package for AC servo (6 axes in total); external axes can be added |

Relative humidity | 10%~90% (no condensation) |

Vibrate | 0.5G or less |

Serial port I/F | |

RS485 (one) RS422 (one) RS232 (one) CAN interface (one) USB interface (one) | |

Altitude | |

Below 1000m above sea level, the maximum ambient temperature decreases by 1% for every 100m increase above 1000m, and can be used at a maximum of 2000m | |

Other | |

No dust, cutting fluid (including coolant), organic solution, oil smoke, water, salt, medicine, anti-rust oil, strong microwave, ultraviolet light, X-ray, radiation exposure | |

Specifications of programming pendant

Overall dimensions | 280(W)*220(D)*120(H)mm (including protrusions) |

gross weight | 0.6KG |

material quality | Reinforced plastic |

display screen | 8-inch color LED, touch screen 640*480 pixels |

protection grade | IP54 |

Cable Length | Standard: 5m; Optional: 15m |

manipulator | |

Selection key, axis operation key, value/application key, mode switching key with key/(teaching mode, playback mode, remote mode), emergency stop key, enable key, 1 USB port | |

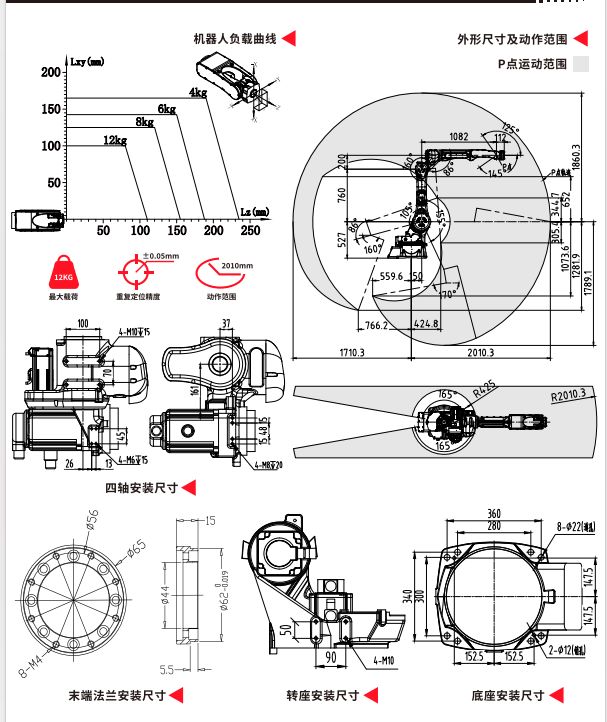

2.MR12-2010

Robot Technical parameter

Model | MR12-2010 | ||

Axis | 6 | ||

Motion radius | 2010mm | ||

Power capacity | 4.5KVA | ||

Payload | 12KG | ||

Repeatability | ±0.05mm | ||

Robot mass | 313KG | ||

Power capacity | Ф10 | ||

Protection class | IP56/IP67 | ||

Signals | Standard 16 in/16 out 24VDC | ||

Install | Floor-standing/bracket-type/inverted-hanging | ||

Moving range&speed | |||

Axis 1 S | Moving speed 203°/s | Moving range ±165° | |

Axis 2 L | Moving speed 203°/s | Moving range from +80°to -145° | |

Axis 3 U | Moving speed 214°/s | Moving range from +145°to -75° | |

Axis 4 R | Moving speed 392°/s | Moving range ±190° | |

Axis 5 B | Moving speed 276°/s | Moving range from +50°to -210° | |

Axis 6 T | Moving speed 1356°/s | Moving range ±220° | |

Axis 4 R(N.m) | 88.5 | ||

Axis 5 B (N.m) | 45.52 | ||

Axis 6 T (N.m) | 32.64 | ||

Control cabinet parameters

Overall dimension | 700(width)*530(depth)*740(height)mm(including protrusions) |

Rough quality | 60KG |

Cooling method | Direct cooling |

Power specifications | AC220V 50/60HZ |

Grounding | Industrial grounding (special grounding with grounding resistance below 1000) |

Input/0utput signal | General signal: input 16, output 16 (16 in 16 out) |

Position control method | Serial communication method EtherCAT.TCP/IP |

Memory capacity | JOB: 200,000 steps, 10,000 robot commands (200M in total) |

LAN(Host link) | Ethercat (1) TCP/IP (1) |

Control mode | Software servo <position control> |

Ambient temperature | When powered on: 0~+45℃, when stored: -20~+60℃ |

Driver unit | Servo package for AC servo (6 axes in total); external axes can be added |

Relative humidity | 10%~90% (no condensation) |

Vibrate | 0.5G or less |

Serial port I/F | |

RS485 (one) RS422 (one) RS232 (one) CAN interface (one) USB interface (one) | |

Altitude | |

Below 1000m above sea level, the maximum ambient temperature decreases by 1% for every 100m increase above 1000m, and can be used at a maximum of 2000m | |

Other | |

No dust, cutting fluid (including coolant), organic solution, oil smoke, water, salt, medicine, anti-rust oil, strong microwave, ultraviolet light, X-ray, radiation exposure | |

Specifications of programming pendant

Overall dimensions | 280(W)*220(D)*120(H)mm (including protrusions) |

gross weight | 0.6KG |

material quality | Reinforced plastic |

display screen | 8-inch color LED, touch screen 640*480 pixels |

protection grade | IP54 |

Cable Length | Standard: 5m; Optional: 15m |

manipulator | |

Selection key, axis operation key, value/application key, mode switching key with key/(teaching mode, playback mode, remote mode), emergency stop key, enable key, 1 USB port | |

Online Inquiry