Other Products Machine

CNC Servo roller feeder / 2in1 rack leveling machine

Product Description

CNC Servo Roller Feeder

Machine pictures for reference

I Environmental conditions required for the equipment:

1 Ambient temperature: -10~40℃;

2 Relative humidity: ≤60%;

3 Working power: AC380V±10%,50HZ±2%;

4Compressed air pressure: 0.5Mpa;

5 Unit direction: facing the front of the punching machine from left to right; (specifically customized)

6 Total equipment power: 5kw;

II Production line composition:

1 2in1 rack leveling machine 1set

2 Servo roller feeder 1set

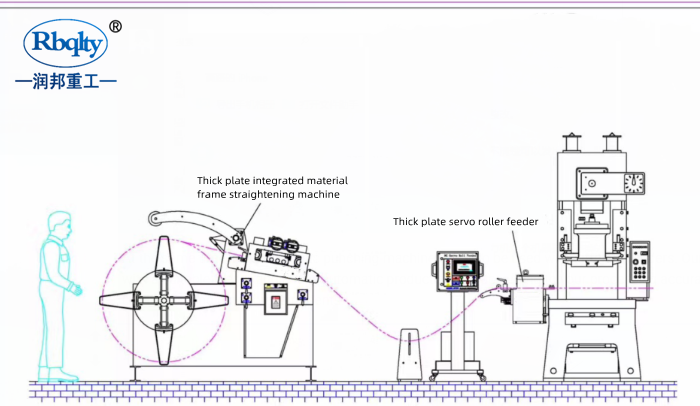

Production line diagram:

Components

Standard configuration of main electrical components and power transmission parts

Number | Name | Matter | Brand |

1 | Servo motor |

| Mitsubishi |

2 | Server Driver |

| Mitsubishi |

3 | PLC |

| Mitsubishi |

4 | air switch |

| Schneider |

5 | AC contactor |

| Schneider |

6 | Intermediate relay |

| Schneider |

7 | Switching power supply |

| Schneider |

8 | HMI | 7 inch | MCGS |

9 | Power switch button |

| CHLI |

10 | Solenoid valve |

| AirTAC MINDMAN |

11 | Bearing |

| NSK,NTN,HRB |

12 | Motor reducer |

| Domestic brand |

13 | Inverter |

| Shihlin |

Optional device: (The standard machine does not include this configuration)

1 2in1 rack leveling machine: Frequency;

2 2in1 rack leveling machine: Material rack pressing arm;

3 2in1 rack leveling machine: Hydraulic expansion of the rack;

4 2in1 rack leveling machine: Correction amount screw lift adjustment;

5 2in1 rack leveling machine: Pneumatic lifting of the feeding wheel of the leveler;

6 Other special requirements can be customized according to requirements;

Technical Parameters

Main Technical Parameters

NO. | Item | Unit | NCF-200 | NCF-300 | NCF-400 | NCF-500 | NCF-600 | NCF-800 |

1 | Material width | mm | 0-200 | 0-300 | 0-400 | 0-500 | 0-600 | 0-800 |

2 | Material thickness | mm | 0.5-3.0 | 0.5-3.0 | 0.5-3.0 | 0.5-3.0 | 0.5-3.0 | 0.5-3.0 |

3 | Feeding roller | piece | up 1 down 1 | up 1 down 1 | up 1 down 1 | up 1 down 1 | up 1 down 1 | up 1 down 1 |

4 | Feed roller | piece | up 1 down 1 | up 1 down 1 | up 1 down 1 | up 1 down 1 | up 1 down 1 | up 1 down 1 |

5 | Leveling roller | piece | up 3 down 4 | up 3 down 4 | up 3 down 4 | up 3 down 4 | up 3 down 4 | up 3 down 4 |

6 | Shelf load | kg | 800 | 1000 | 1500 | 2000 | 2000 | 3000 |

7 | Coil diameter | mm | Φ480-Φ520 | Φ480-Φ520 | Φ480-Φ520 | Φ480-Φ520 | Φ480-Φ520 | Φ480-Φ520 |

8 | Coil outer diameter | mm | Φ1200 | Φ1200 | Φ1200 | Φ1200 | Φ1200 | Φ1200 |

9 | Expansion method of material rack |

| Manual expansion | Manual expansion | Manual expansion | Manual expansion | Manual expansion | Manual expansion |

10 | Rack power mode |

| Passive | Passive | Passive | Passive | Passive | Passive |

11 | Feeding speed | m/min | 16 | 16 | 16 | 16 | 16 | 16 |

12 | Air pressure relaxation speed | spm | 100 | 100 | 100 | 100 | 100 | 100 |

13 | Feeding length | mm | 0-9999.99 | 0-9999.99 | 0-9999.99 | 0-9999.99 | 0-9999.99 | 0-9999.99 |

14 | Feeding line height | mm | 120±50 | 120±50 | 120±50 | 120±50 | 120±50 | 120±50 |

15 | Servo motor | kw | AC1.0 | AC1.0 | AC1.5 | AC1.5 | AC1.5 | AC3.0 |

16 | Leveling motor | kw | AC0.75 | AC0.75 | AC1.5 | AC2.2 | AC2.2 | AC3.0 |

17 | Rack motor | kw | / | / | / | / | / | / |

Online Inquiry

E-mail:rbzg@rbqlty.com

Address: Bowang Industrial Park, Bowang District, Ma'anshan, Anhui

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.