Home Products

Press Brake

CNC Hydraulic Press Brake

Steel plate welded structure, hydraulic transmission, accumulator return, holistic processed, vibrating toeliminate stress, high strength and good rigidity.

Product Description

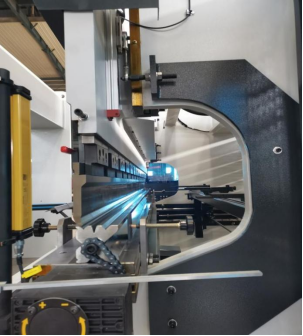

DA53T 300T4000 4+1Axis CNC Press Brake Machine

Back Gauge Safety Fence

1. Steel plate welded structure, hydraulic transmission, accumulator return, holistic processed, vibrating toeliminate stress, high strength and good rigidity.

2. Mechanical torque system makes sure the synchronization of cylinders.

3. The stroke of slider and back gauge is adjusted automatically by double servo motors or transducer, and showed on CNC Mechanical torque or NC control panel.

4. Slanting wedges can be chosen to install on the top dies which can be adjusted by hands or automatically. Hydraulic compensation system is installed under the worktable.

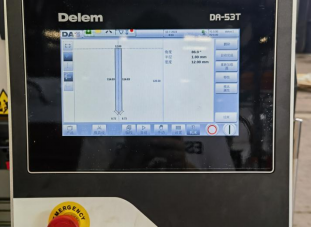

CNC DA-53T System Introduction

Standard

- Colour high brightness LCD display

- 10.1" wide screen TFT

- LED backlight

- 1024 x 600 pixels

- Industrial grade touch screen

- Storage capacity 1 GB

- Data backup / restore via USB

- Integrated valve amplifier

- Power-down memorisation

- Profile-53TL offline software

Main Functions

· “Hot-key” touch navigation

· 10.1" high resolution colour TFT

· Up to 4 axes (Y1,Y2 + 2 aux. axes)

· Crowning control

· Tool / material / product library

· Servo and frequency inverter control

· Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

· USB memory stick interfacing

· Profile-T offline software solution

A CNC hydraulic press brake is a highly precise and efficient machine. It utilizes hydraulic power for operation. The CNC (Computer Numerical Control) system enables accurate control of the bending process, allowing for complex and precise bends. It is widely used in metalworking industries for shaping sheet metal with high accuracy and repeatability, enhancing productivity and ensuring high - quality end products.

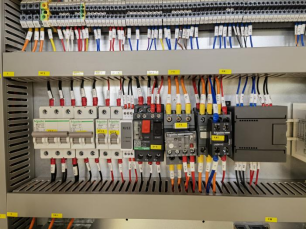

Components

Machine parts

Fast mold clamp |  CNC system |

Front support + guide rail |  Multi-V mold |

Electronic system |  Hydraulic Valve |

Main motor |  Servo Drive |

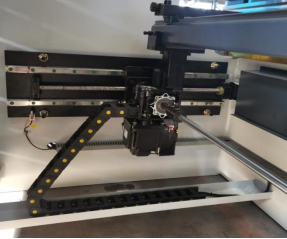

Back gauge |  Double guide rail for back gauge beam |

Z-axis operation finger |  Ball screw + linear guide |

V-axis electrical compensation |  Grating ruler |

Foot switch |  Oil pump |

Machine optional parts

CNC control system |  Up and down stop finger |

Laser protection |  Air cooled |

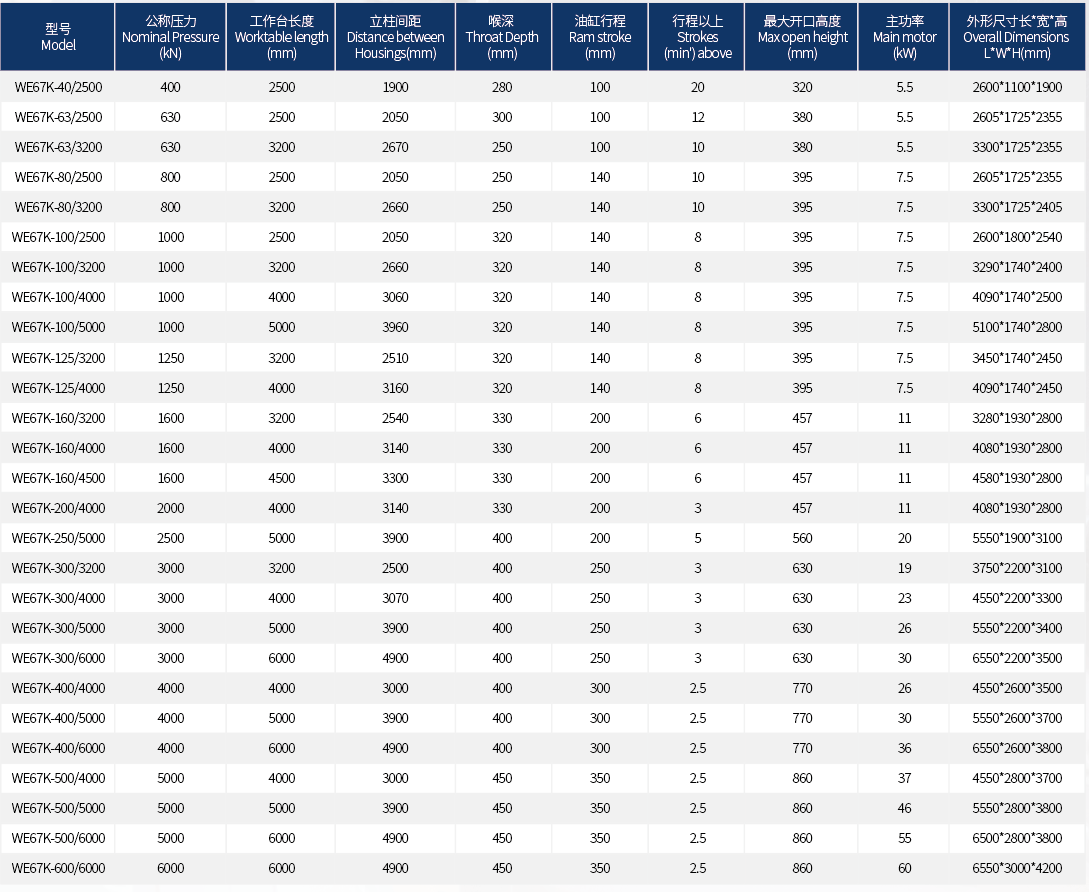

Technical Parameters

Machine Axis

Online Inquiry

E-mail:rbzg@rbqlty.com

Address: Bowang Industrial Park, Bowang District, Ma'anshan, Anhui

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.