Manufacturing Experience

Exporting Countries

Warranty Period

Active Employees

Main Products

At the cutting edge of sheet metal cutting and bending, we're committed to delivering expertly designed equipment that perfectly fits your needs.

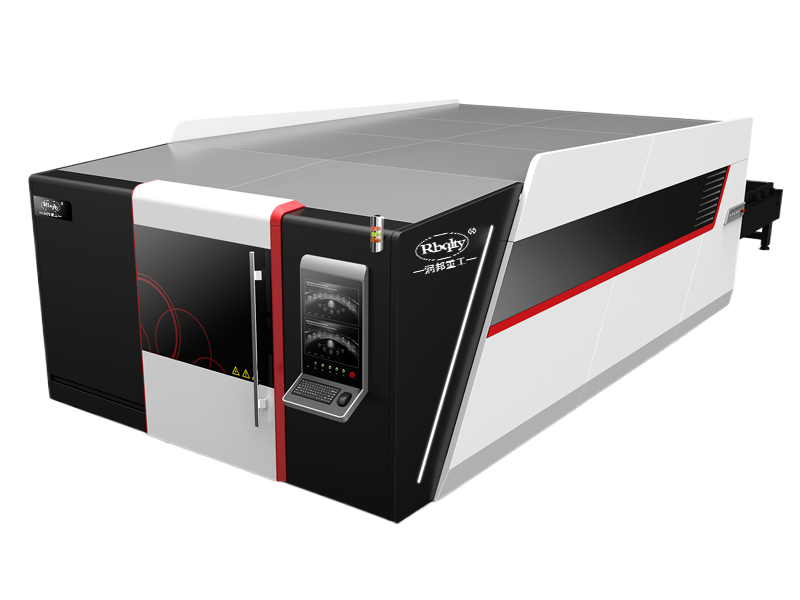

Closed Exchange Table Laser Cutting Machine

Fiber laser cutting machine adopts the advanced fiber laser output laser beam of high energy density, and focused on the workpiece surface, making areas on the workpiece are melting and gasify instantly by ultra fine focal spotlight; Automatic cutting is achieved by moving the light spot through the CNC mechanical system. It is one of the high-tech equipment with features of advanced optical fiber laser technology, numerical control technology, precision machinery technology.

Back gauge controlling; General motors control; Intelligent positioning;Two programmable digital output; Work piece counting40 program memory 25 steps for each program; Unilateral positioning; Concession function;One key to parameter backup and recovery; Metric system; Chinese/English.

CNC 4 Roller Hydraulic Rolling Machine

The machine belongs to a four-roll plate reel machine, used for manufacturing pressure vessels and other industries of the pre-bending, winding, and has the function of correction, rough leveling.

Fiber laser cutting machine adopts the advanced fiber laser output laser beam of high energy density, and focused on the workpiece surface, making areas on the workpiece are melting and gasify instantly by ultra fine focal spotlight; Automatic cutting is achieved by moving the light spot through the CNC mechanical system. It is one of the high-tech equipment with features of advanced optical fiber laser technology, numerical control technology, precision machinery technology.

Steel plate welded structure, hydraulic transmission, accumulator return, holistic processed, vibrating toeliminate stress, high strength and good rigidity.

Pneumatic Punching Machine with feeder

This series of press frame is welded by steel plates, small deformation, good rigidity.This series of machines adopts pneumatic friction clutch-brake combination, long service life, low noise, stable transmission.

ABOUT

Focus on the complete set of metal sheet fabrication equipment

Anhui Runbang Heavy Industry Machinery Co., Ltd. is a modern enterprise focusing on the research and development, manufacturing, sales and service of a complete set of metal sheet processing equipment. Its brands are RBQLTY,CNCCOLGAR,MTCNC. The company has a group of knowledgeable, professional and young technical teams dedicated to the development and research of fiber laser cutting, bending, shearing, punching press, plate rolling, air duct making machines, and other sheet metal processing machines., and meeting the special order requirements of users.

Read More ⟶CORPORATE CULTURE

Choose with confidence and serve with heart. Use high-quality machine to promote the prestige of the great country!

CERTIFICATE

The company has passed ISO9001 quality system certification and EU export CE certification, and has established a comprehensive market service system and mature production processes.

FACTORY WORKSHOP

A standardized production workshop where every detail of each process must undergo rigorous inspection and testing to ensure compliance with standards.

Exhibition Information

To provide customers with high-quality products, satisfactory services, and competitive prices

Become an agent of Rbqlty

you will get

Runbang authorizes like-minded qualified partners as local agents to provide better support in local and surrounding markets. Our goal is to cooperate and develop together to achieve mutual benefit and sustainable development! Welcome to choose Rbqlty&CNCCOLGAR&MTNC as your favorite machine brand, waiting for you to join!

Read More ⟶Company's publicity tools are shared with agents

The latest machine design and industry consulting sharing

Lower agency price list and full set of machine details

Perfect after-sales system, agents have no after-sales worries

Rbqlty is trusted by customers around the world

We've established partnerships with globally renowned brands, further solidifying our reputation as a trusted leader in the industry.

Senior Technical Team

Several senior engineers and technicians provide technical support

Selected and recognized by many sheet metal processing companies.

Provide users with the most considerate and reasonable sheet metal processing solutions

Years of Experience

Focus on sheet metal price equipment research and development, design

Selected and recognized by many sheet metal processing companies.

Users are spread across more than 160 countries and regions including Southeast Asia, the Middle East, the European Union, South Africa, and South America

Customer Service Team

Pre-sales product selection, budget assessment, project inspection

During-sales equipment installation, process debugging, operation training

After-sales tracking service, 1-hour quick response, 24-hour on-site solution

Latest Blog

Stay informed and inspired by diving into our newest article.

2025-07-15

From Concept to Creation: The Comprehensive Guide to the CNC Hydraulic Press Brake Process

From Concept to Creation: The Comprehensive Guide to the CNC Hydraulic Press Brake Process The world of manufacturing, especially in metal fabrication, has seen significant advancements over the years. One of the most pivotal developments is the **CNC hydraulic press brake**, a machine that has revolutionized the bending process. In this guide, we will take a detailed look at the CNC hydraulic pre

2025-07-14

Exploring the Advantages of CNC Laser Cutting Machine Lines in Modern Manufacturing

CNC (Computer Numerical Control) laser cutting machines represent a significant advancement in cutting technology. They utilize a high-powered laser beam to cut through various materials with remarkable precision, making them an essential tool in modern manufacturing. One of the primary advantages of using a CNC laser cutting machine line is the unparalleled accuracy it offers. Traditional cutting

2025-07-13

Transform Your Production: The Role of CNC Laser Cutting Machine Lines

Transform Your Production: The Role of CNC Laser Cutting Machine Lines Table of Contents 1. Introduction to CNC Laser Cutting Technology 2. The Evolution of CNC Laser Cutting Machines 3. Key Components of CNC Laser Cutting Machine Lines 3.1 Laser Source Types 3.2 Control Systems and Software 3.3 Cutting Tables and Fixtures 4. Advantages of CNC Laser Cutting Machines in Industrial Applications 4.1

2025-07-12

Understanding Industrial Press Brakes: Essential Insights for the Manufacturing Sector

Industrial press brakes are pivotal in the manufacturing sector, especially in metal forming processes. They are machines specifically designed to bend, fold, and shape sheet metal into various forms. Understanding the intricacies of these machines can significantly enhance productivity and efficiency in manufacturing operations. At their core, industrial press brakes utilize significant force to

Request A Quote

Contact our expert team to provide you professional suggestions.