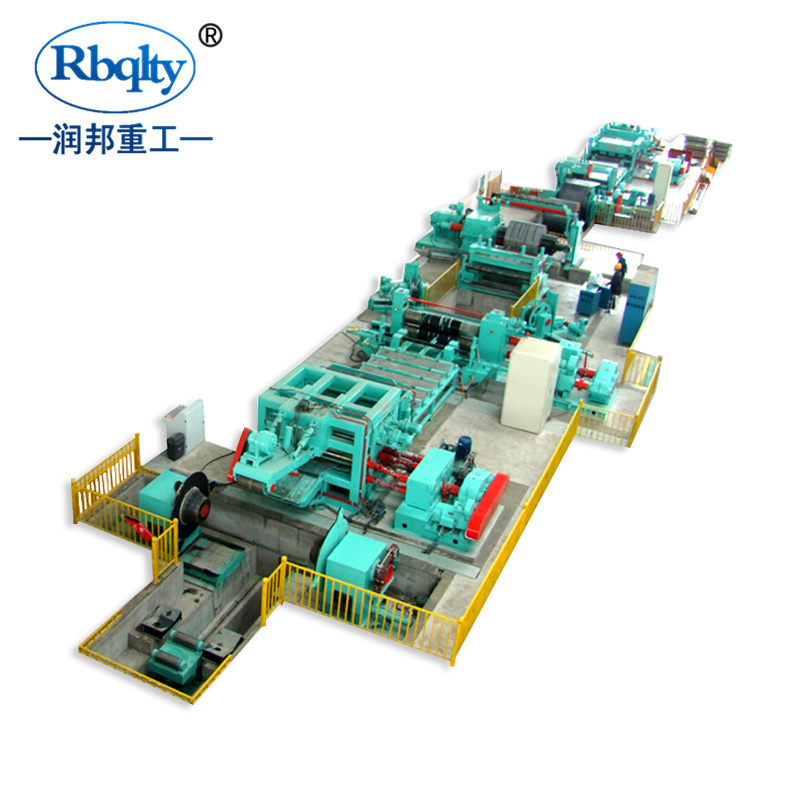

Coil Steel Cutting Line/Slitting Line Machine

key word:

Coil Steel Cutting Line/Slitting Line Machine

Text and image details

Automatic High Speed Precision Metal Sheet Steel coil Slitting Line With Siemens PLC

Decoiling, Slitting & Recoiling Line

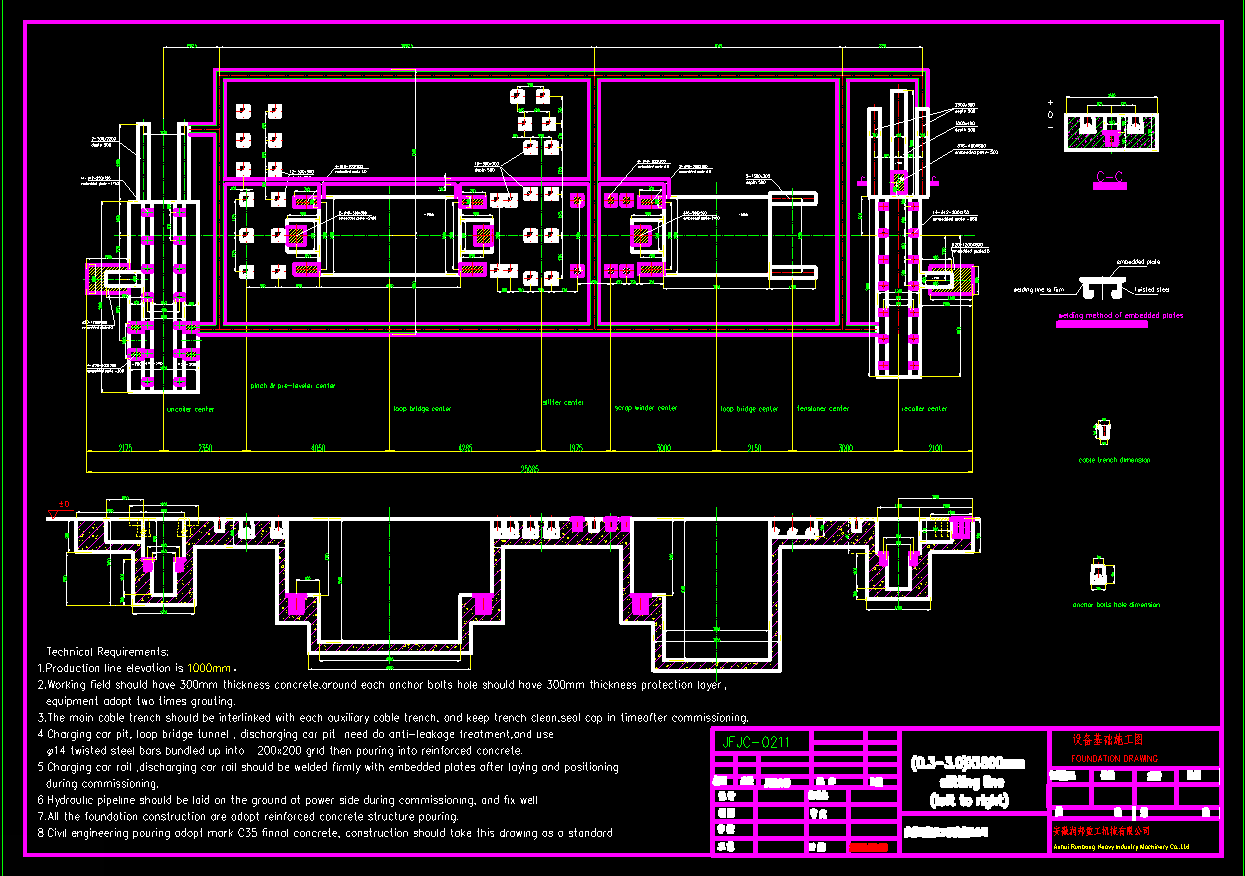

(0.3-3)×1800mm

Ⅰ. Technical parameters:

- Raw material parameters:

1. 1 The coil meterial: σs≤235Mpa CR, Galvanized plate;

1. 2 The thickness of the coil: 0.3-3mm;

1. 3 The width of the coil: 800-1800mm

1. 4 The ID of the coil: φ508mm φ610mm;

1. 5 The OD of the coil:φ1600mm

1. 6 The weight of the coil: 15T;

2. Equipment parameters:

2. 1 Slitting minimum strip :width:≥50mm;

2. 2 Slitting precision: Width tolerance ±0.1mm;

2. 3 Slitting pieces: 0.3-1mm≤10pcs;

1.1-2mm≤7pcs;

2.1-3mm≤5pcs;

2. 4 Material of tool shaft: φ220mm;Material 42CrMo;

2. 5 Blade specifications: φ220×φ340×15mm;( prepare by users)

2. 6 Blade material: 70Sicrv, Hardness HRC 56-60;

2. 7 Recoiling speed: 0-120m/min

2. 8 Recoiling ID: φ508mm;

2. 9 The standard height of the production line:1000mm;

3. Main electric parameters:

3. 1 Using power: 380V±10% three-phased electricity, 50Hz

3. 2 Control voltage: 220V±10%

3. 3 Electric control cabinet: IP40

3. 4 Production line operation cabinet: IP45

3. 5 Gross installed capacit:208.5Kw

4. Using environment:

4. 1 Temperature: -5-45°

4. 2 Humidity: 20-85%PH(without dew)

4. 3 Sea level: Under 1000m

4. 4 Strength of earthquake: 6 magnitude

5. Craftsman parameters of the line:

5. 1 Feeding direction: to be confirmed normally left to right

5. 2 Number of operators: 3-5 people

5. 3 The color of the line: It could be decided by the buyer.

II. Process flow:

Carry coil→ load coil →decoil→ press-guide shovel-head→ pinching→head cutting

→looping,transition→ guide→ slitting →transition→ looping & storage→

↘scrap rewinding

pre-separation, damping, press- separation →recoiling→ packing→ discharging (electric control system, hydraulic system)

Ⅲ. Equipment composition:

1. “V ” shape coil-loading

Type: Saddle-type

Material: Steel-plate welded strcture parts

Founcation: It is for storing the steel coil and transport loaded coil to prevent it from crashing.

2. Hydraulic coil-loading car: Weight capacity:15T

It consists of bottom base, up-support base, car shaft, car wheel, bearing, guiding pillar, guidding sleeve, lifting cylinder, running motor,etc This car can carry coil make it lift up and down to the center of decoiler. the lifting of the car is finished by oil cylinder, the running of the car is driven by motor.

Type: Four wheels Guide-track styled walking,

Main material: steel-welding parts

Power of transmission: 3kw cycloidal motor

Power of Lift: Oil cylinderφ160x700mm

Specification: loading weight 15000kg,

Coil O.D.: ≤φ1600mm

3. Hydraulic cantilever & expansion decoiler: loading weight: 15T

It consists of bracket, decoiling shaft, expansion-keeping disc, decoiler arc plate, hydraulic expansion angled-lift splits harmomegathus mechanism, equipped with damping & braking mechanism, bearing base, hydraulic support arm, etc.

Type:hydraulic cantilever expansion type

Scope of expansion: φ470-520mm, add pads to φ610mm

Main material: welded steel plate part of frame, main axis with heat treatment

Expansion Oil cylinder: φ160×1000mm Rotating cylinder

Expansion of rose oil cylinder: φ160mm x 95mm 2pcs

Suitable wide: 800-1800mm

Specifications: Weight capacity 15000Kg

O.D. of the suitable coil: ≤ φ1600mm

4. Hydraulic press-guide, shovel-head mechanism:

①Hydraulic press-guide mechanism: It consists of hydraulic press-guide arm, press-guide rubber wheel, bearing base, chain & sprocket wheel transmission mechanism, equipped with 2.2kw cycloidal speed motor etc.

Type: hydraulic Cantilever styled, hydraulic motor press-guide

Main material: Steel structure pieces of press-guide arm, press-guide roller with polyurethane

Oil cylinder: φ80×400mm

Press-guide roll: φ310×400mm

Press-guide motor: 2.2kw cycloidal speed motor

② Hydraulic shovel-head mechanism: It consists of shovel-head shell, hydraulic flexible shovel-head plate, shovel-head hydraulic lifting & balance mechanism etc.

Type: Hydraulic lifting & flexible style

Main material: Steel structures pieces bracket,45# shovel plate

Oil cylinder spefication: Liftingφ50×400mm flexibleφ63×500mm

5. Hydraulic pinching

① hydraulic pinching machine:

It consists of base, bracket, beam, pinching sliding block axle seat, 2 pinching rolls, upper pinching roll hydrauilc press-down & lifting mechanism, etc.

Type: 2 pinching rolls

Main material: steel structure pieces base, bracket

Pinching rollers: 42CrMo, Mid frequency hardening hardness HRC54-58 The surface is plated by hard chrome HRC 56-60

Pinching oil cylinder: φ100×180mm 2pcs

Type of lift: press down & pinch by oil cylinder

Oil cylinder spefication:φ63×120mm

② Pinching power mechanism:

It consists of base, reducer, 22kw AC motor, coupling, clutch, universal drive shaft, clutch, etc.

Type: pinching distributor box transmission

Main material: steel structure pieces base, welded steel plate gear box

Gear: 40Cr forging, surface with high-frequency quenching

Universal joint: SWC1180

Power: 22kw AC motor (frequency converting control)

6. Hydraulic head-shearer: .3×1800 mm ( Hydraulic head & tail shearing)

7. looping & transition:

It consists of bracket, Arc transition rollaway nest, bearing base, moving lift platform, veer roller, hydraulic lifting up & down mechanism, etc.

Looping pit: 2.5m×1.0m×2.5m (L×W×D) cement watering

8. Guide & centralization mechanism:

It consists of guide-track base, guide pillar, screw mandrel adjustable & centralizing mechanism, active guide base, multi-rolled backup wheel, etc.

Type: Vertical roller guiding, screw rod centralizing

Main material: square pipe of bracket, 45# guide pillar grinded

Vertical rod specifications: φ90×100mm 2 pcs high-frequency quenching

Carrier Roller specification: φ62×1800mm hard chrome surface.

Rectifying form: double lead screw with one side manual

Adjustable range: 800-1800mm

9. Slitter:

It consists of 2sets of main-unit part & power part..

① Power part:

It consists of power base, reducer, 55 kw DC speed-regulation motor, counter-tooth distribution gear box, coupling, clutch, universal cross gimbal shaft etc.

Type: Reducer equiped with gear counter-tooth distribution box

Main material: Steel structure pieces base, distribution box

Gear: 40Cr heat-treatment, High-frequency quenching

Power: 55Kw DC speed-regulation motor equipped with SSD 590 Controller

② Main-unit part:

It consists of base, fixed-styled bracket, sliding block of tool shaft, tool shaft two pieces, active bracket, moveable bracket hydraulic entry-exit & knife changing and adjusting mechanism, upper tool shaft simultaneous lifting & press-down adjustable mechanism, etc. ( blades, spacers, rubber ring prepared by user)

Type: disc type slitting

Main material: Welded pieces base, forged bearing sliding block

Tool shaft: 42CrMo

Moveable oil cylinder: φ80×600mm

Material of blade: 70Sicrv. Hardness: HRC 56-60

Specification of blade: φ220×φ340×15mm;

10. Rollerway worktable:

It consists of bracket, bearing base, rollerway, supporting plate, etc.

Type: rollerway style, with swing table

Main material: steel pipe of frame, rollerway by seamless pipe

Spefication:2500mm×180mm x 1000mm

11. Scrap-rewinder mechanism:

It consists of bracket, rewinding shaft, double rewinding disc, guide wheel, rows agency, 3kw cycloid –pin wheel motor, etc.

Type: friction tension control roll up type automatic wiring

Main material: Welded pieces base, frame,

Power : 3kw cycloid –pin wheel motor

12. Looping & hydraulic material-storage bridge:

It consists of bracket, bearing, active lifting platform, steering roll, hydraulic lifting up & down mechanism etc.

Main material: structure steel platform

Specification of looping pit: Length3.0m×Width2.2m×Depth4.5m

irrigated by cement

13. Pre-seperation, hydraulic damping & tension mechanism, hydraulic press-seperation

Mechanism, hydraulic support plate mechanism:

It consists of base, bearing base, pre-seperation shaft, material-pressing roller mechanism, hydraulic damping bracket, damping plate, damping plate hydraulic lifting & press-down mechanism, tension frame, press-seperation bracket, press-seperation shaft, press-seperation hydraulic lifting up & press-down mechanism, equipped with material-seperation sheet, spacer etc.

Type: Hydraulic clamping-board damping style,

Main material: wool felt damping plate, polyurethane tension steering

Preassigned sheets: φ220 xφ80 x4mm material: 65Mn

Tension roller: φ350 x 1900mm

Damping cylinder: φ80×120mm

Press-seperation cylinder: φ80×300mm 2pcs

Hyraulic pressure plate: suitable wide: 1800mm

The pallet balances the oil cylinder: φ50 x 300mm

14. Recoiling Line: Weight capacity:

It consists of base, speed-reduction gear transmission box, recoiling shaft,

arc-shaped plate, hydraulic recoiling expand mechanism, swallowtail slot slant slider harmomegathus mechanism, hydraulic mouth of tongs clamping mechanism, arrester mechanism, coupling, hydraulic active supporting arm, supporting base, equipped with 132Kw DC speed-regulation motor etc.

Type: hydraulic oblique T expansion, hydraulic jaw clamping

Main material: steel welded structural parts stand, distribution box

Specification of recoiling drum: φ508 x1900 mm

Maximum expansion distance: 50mm

Collapsible cylinder; φ160mm x 96mm

Recoiling shaft material: 42CrMoV, Heat treatment

Support cylinder: φ125 x 580mm

Winding entrainment: hydraulic linkage inclined clamp type

Recoiling power: 132Kw DC speed-regulation motor. equipped with SSD 590 Controll er

15. Hydraulic discharging car:

It consists of frame, V-shaped supporting base, hydraulic lifting up & down mechanism, car shaft & wheel, guiding pillar, guiding sleeve, running motor,etc.This car carry seperated strips, hydraulic lifting, it is driven by four-wheeled guide rail.

Type: Guide-rail walking wheel car, hydraulic lifting, driven by motor

Main material: steel-plate welded structure of body

Walking wheel:42CrMo surface hardening

Guiding pillar: 45# steel heat treatment

Specification of oil cylinder: Liftingφ160×700mm

Running motor: 3kw cycloidal motor

Applicable to steel coil: O.D. ≤φ1600mm

Specification: 15000kg

16. Electric control system:

It consisits of main operation cabinet, vice operation table, DC electric cabinet, etc, slitting & recoiline DC motocr equiped with digital DC speed-adjusting divice( SSD 590C) , Janpanese MITSUBISHI PLC, which carrying out whole line linkage, touched screen with Man-machine conversation, etc.

The equipment set safty protection, emergency-stop and machine-stop lamp, etc.

Using power: 380V, 50Hz

Control voltage: 220V, 50Hz

17. Hydraulic pneumatic system: (Users prepare air)

Hydraulic station consists of hydraulic pump, valve plate, hydraulic inverting valve, spillover valve, defending pressure valve and adjusting valve,high pressure soft and hard pipes, joints, etc.

Transmission power: 7.5kw-4

Rated pressure: 16Mpa, and the actual press 10-12 Mpa

Flow rate:40L/min

Air force 0.5-0.9Mpa 0.9 cube (without water)

Ⅳ: Acquired factory Requirements:

1.Electrical pressure: 380V±10%, frequency: 50Hz±10%;

2.Using environment: be suitable for -5℃-50℃,humidity:20%-80% (without dew)

3. Equipment foundation: Protection guardrail, hydraulic oil

4. Air force 0.5-0.9Mpa 0.9 cube (without water)